03 Mar Sensera System Level Product Success Story

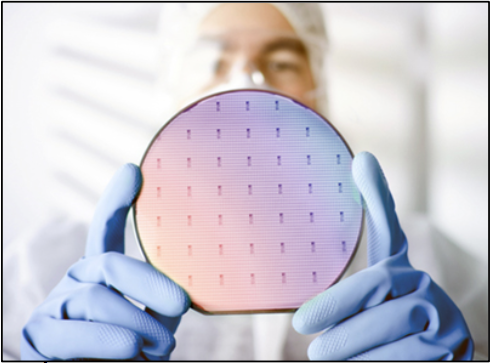

Microfabrication Benefit OEM System: Miniaturization – portable “System-on-Chip”

Review the following medical device assembly success story from JD Technologies, LLC and Sensera.

Benefits:

Helping Our Customers Succeed

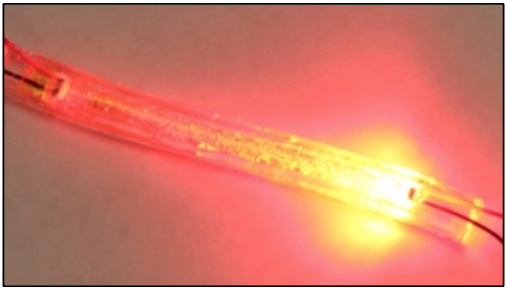

A large optical system OEM needed to meet challenging performance requirements while producing a system that was smaller and lighter. They had a system level product that was functioning as a prototype but lacked the final microfabrication process refinement for a key component embedded in the system.

Solution

Sensera engineering was able to refine the process and produce a miniature – portable “System-on-Chip” that made the product more producible and cost effective. Sensera also implemented their Matched-to-Market . Sensera’s Matched-to-Market is an approach to volume manufacturing, whereby they understand (listen) and manufacture (execute) to the demands specific to their customers’ volume requirements whether it is a custom design, small run manufacturing or like this specific success story, a transition to high throughput demand.

Result

All performance requirements were met or exceeded while reducing weight and volume. The production solution afforded our customer a manufacturing process that was repeatable and optimized the supply chain while beating cost targets.

Sorry, the comment form is closed at this time.